Series VR / VRX Pneumatic coolers

Excellent performances, optimised technical features, wide range, and customised versions

The VR / VRX SERIES coolers are state-of-the-art solutions for compressed-air cooling based on the principle of the Vortex Tube. The excellent performances of flow-rate and ΔT generated, the design, the fastenings that make them extremely versatile to mount, and the possibility to combine them in a patented system with the air amplifiers (to use the hot air flow), offer customers an innovative, effective, and inexpensive solution to cool down metal and plastic parts, electric and electronic control cabinets, and mechanical applications. All this with a simple connection to the compressed-air line.

- ∆t compared to the air supply temperature up to -40 °C for cold flow and +60°C for hot flow

- Easy to install, by means of flanges or neodymium magnet

- Patented hot air recovery system in combination with AM Series amplifiers

- Made from corrosion-resistant material

- No moving parts and, therefore, not subject to wear

- No electricity or chemical products required

- No sparks or interferences

- Instant operation

- Reliable and maintenance-free

Description of vortex tubes

The Ranque-Hilsch tube, in the industrial sector better known as “Vortex tube”, is a device that splits a compressed-air flow in 2 separate streams: one of cold air, and one of hot air. The core of the system is the vortex chamber, which is connected to 2 opposed tubes, one of which features a valve. When the compressed air is injected tangentially in the chamber, this causes the rotary movement of air towards one of the exits. This vortex moves rotating at high speed and brushing against the inner side of the tube, increasing in temperature; the valve placed at the hot air outlet enables some of it to be exhausted. The remaining part goes back, creating a low pressure vortex moving towards the other exit and giving away heat to the first vortex. So, this flow is much colder. The ΔT generated is inversely proportional to the volume of the flow. The differences in temperature are considerable and can reach -40°C for the cold flow and 60°C for the hot flow. In the industrial field the Vortex tubes have been employed for a long time and have found a variety of applications in which they offer a major added value. They have great cooling performances, are very easy to install and have instant operation, have no moving part and therefore are maintenance-free. Plus, they do not require electric power, so they are suitable for dangerous environments and humid areas. If the application enables their use, they are price-worthier than electric coolers. Our coolers SERIES VR and VRX, beside the excellent performances in comparison to the other products in the market, were designed to be easily customised according to customers’ demands.

Cooler Air Saving – Patented system

VR Series coolers and AM Series amplifiers used together to pump cool air and extract warm air from an electrical cabinet at the same time, using a single compressed air delivery duct.

- Effective electrical cabinet ventilation

- Reduction of compressed air consumption

- Optimised cooling results

No matter how much cool air is pumped into an electrical cabinet, the effectiveness and efficiency of cooling will never be optimal unless the warm air generated by the electrical components is not properly ventilated at the same time. With ventilation we mean both the creation of convection flows inside the cabinet which effectively distribute the air around the components and the actual extraction of warm air from the cabinet itself.

Using the Cooler Air Saving patented system by Simian Project, two results are obtained: the first, using the VR Series coolers, is the rapid, precise cooling of the components which heat the cabinet the most, due to the flexibility of installation (brackets and magnets) and the fact that the flow of cool air onto the main heat sources can be precisely directed (using adjustable nozzles); the second is the proper ventilation of the electrical cabinet given the extraction and blowing power generated by the AM Series air flow amplifiers, fed directly by the air flow discharged from the cooler.

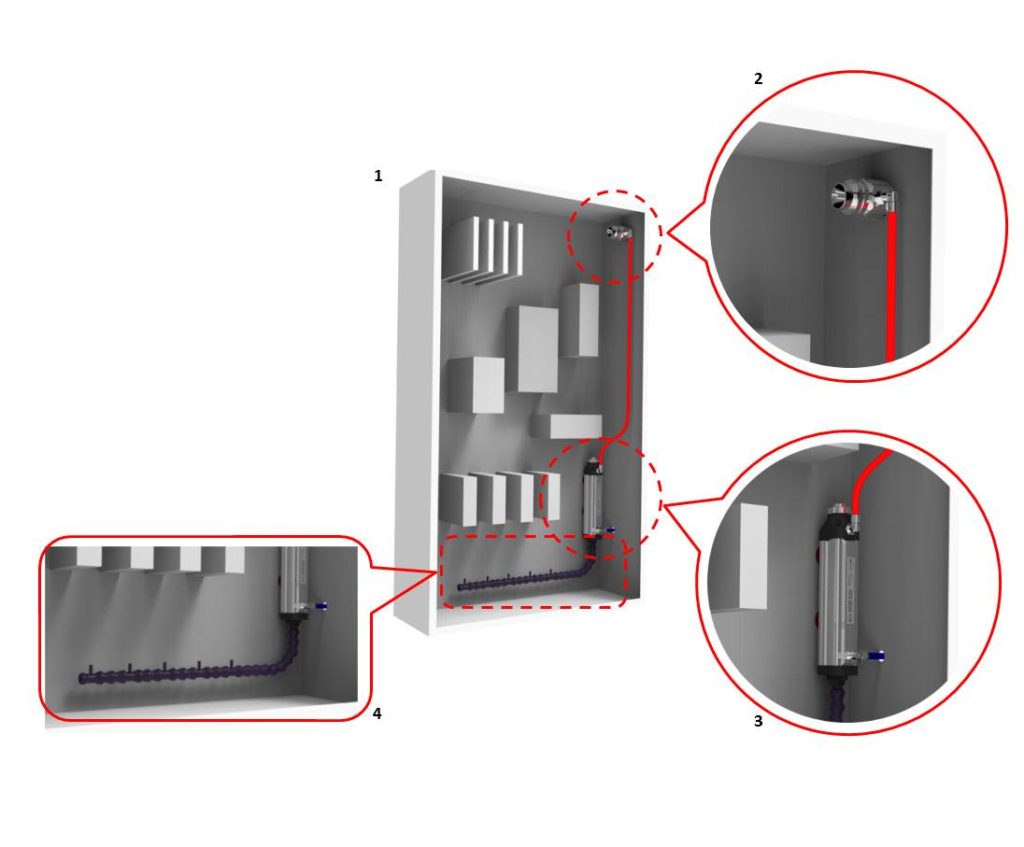

System set up inside an electrical cabinet

The VRX-500 cooler (fig.1) is fed externally with compressed air; the flow of cool air is directed, using special adjustable nozzles, onto the electrical components which give off the most heat, whilst the discharge of warm exhaust air is channelled by the red pipe (fig. 3) and fed into the AM Series amplifier;

The amplifier (fig.2) is fitted in the top right-hand side of the electrical cabinet; the feed-through fitting allows it to intake and extract air from the cabinet; in the example of the diagram, its position in the upper part of the cabinet ensures that extraction occurs where the most hot air accumulates and that even the electrical components located on the opposite side to the direct source of cool air remain at a temperature suitable for optimal functioning

Even where feed-through fitting is not possible (for example in the event of installations in cabinets where IP protection must be guaranteed), the fitting of the amplifier inside the cabinet ensures forced recycling of air, which eliminates the concentration of warm air in the areas located furthest away from sources of cool air.

The patented system also works well together with industrial air-conditioners in electrical cabinets with the following characteristics:

- Large electrical cabinets where the cool air generated by the air-conditioner has trouble reaching all parts of the cabinet;

- Electrical cabinets with electrical components laid out in such a way that the convection of air around the components is tricky;

- Electrical cabinets where the heat is generated by a few components which are located far from the area where the air-conditioner pumps in the cool air;

N.B.: the Cooler Air Saving system works with VRX-300, VRX-500 and VRX-1000 coolers together with AM-20 and AM-40 amplifiers

Supplier's website